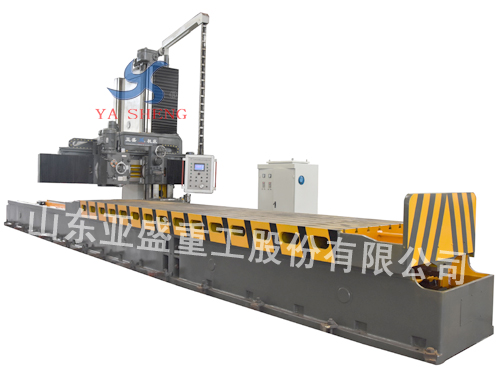

| BXM1010-20 series heavy - duty cantilever planing milling machine |

|

BXM1010-20 series heavy - duty cantilever planing milling machine Introduction to machine tools Yansheng Machine Technology Center cantilever projectdepartment brings together many well-known domestic manufacturers engaged in cantileverplaner design, processing, assembly, technology, quality inspection of the senior workers,experts, bringing together advanced technology at home and abroad, the use of advancedservo control and transmission technology, The series of machine table with a bearingcapacity to meet the three functions of the milling machine in the 25mm a 70m / min rangeof smooth operation, to achieve the plane milling machine plane features. The overall structure of the machine The BXMl010-20 series cantilever milling machineis fixed on the foundation, and the table is reciprocated along the bed guide. The column isconnected to the right side of the bed. The beam and the cantilever are connected to moveup and down along the column guide. Cantilever and Column for the electronic control ofmechanical locking. Beams, columns may need to configure the planing head, boring andmilling head, grinding head and other functional components (user-defined) Basic parts of the process of protection Machine basic parts from the bed, tablecolumn, beams, cantilever, slide plate and other components. Machine tool large HT250 highquality alloy wear-resistant cast iron, the vibration aging of a furnace when the aging of avibration aging a roughing a vibration aging half of the finishing a hot furnace aging avibration aging of a finishing to eliminate the workpiece stress to ensure that the machineLong-term operation accuracy.

Guide wear Rails with "super audio quenching" after grinding treatment, high hardnesswear resistance, the table paste guide rails, with high wear resistance, low friction, shockabsorption and other characteristics, so that the machine can maintain long-term accuracy Main movement The use of Yasheng Heavy Industries independent research anddevelopment four-speed planer, milling, grinding multi-function gearbox, controlled by theAC servo stepless speed control electronic control system, mechanical transmission for highstrength worm, high precision rack drive, to achieve low speed, Drive (30-40% less energythan the DC motor group) to ensure fast shaving efficient, low speed milling, grinding runsmoothly. Control System For the digital AC servo control system, includingprogrammable PLC central processing unit and intelligent power amplifier, to achieve theexchange of variable frequency motor stepless speed requlation, with smooth operation, setaccurate, high efficiency. Main features Planing for the BJl 3 electromagnetic knife knife, milling head for theTaiwan Gongyang technology assembly, at the same time with boring, milling, drilling andother functions, configure the right angle milling head, universal milling head and otheraccessories can be a fixture to achieve five-sided processing The Grinding head can beequipped with high-precision static grinding head and bearing peripheral grinding head andace grinding head

|

Group's Website

Web Portals

Industry Website